just in time for you to take your fenders off for summer, here is the long past due blog about a Haaanjo Fender factory visit from my last trip to Tokyo. We were being shown around the sprawling city on bikes by our gracious hosts at Blue Lug, and they’d suggested we make a stop at Hanjo — glad we did!

we were greeted by the 3rd generation of a family who began this enterprise in 1949, Tomoyuki Shimamura. Tomoyuki is a soft spoken progeny of the nicest fenders in the world who took the time out of his day to kindly show us around the factory and residence that he and his family had built in 1990. I have taken a few images from the Hanjo website, including the photo of said factory residence bellow:

very unassuming for a company that has had such an outsized influence on what J.P. Weigle refers to as “Le Flow”. I think you know what I am talking about, but incase not — when nice metal fenders are properly installed with perfect “shore lines” (equal distance betwixt tire and fender through the radius), and the whole bike from front to back just, you know, flows. French Fender Day has always been about Japanese fenders — the highest quality in the world made in this little factory by Haaaanjo.

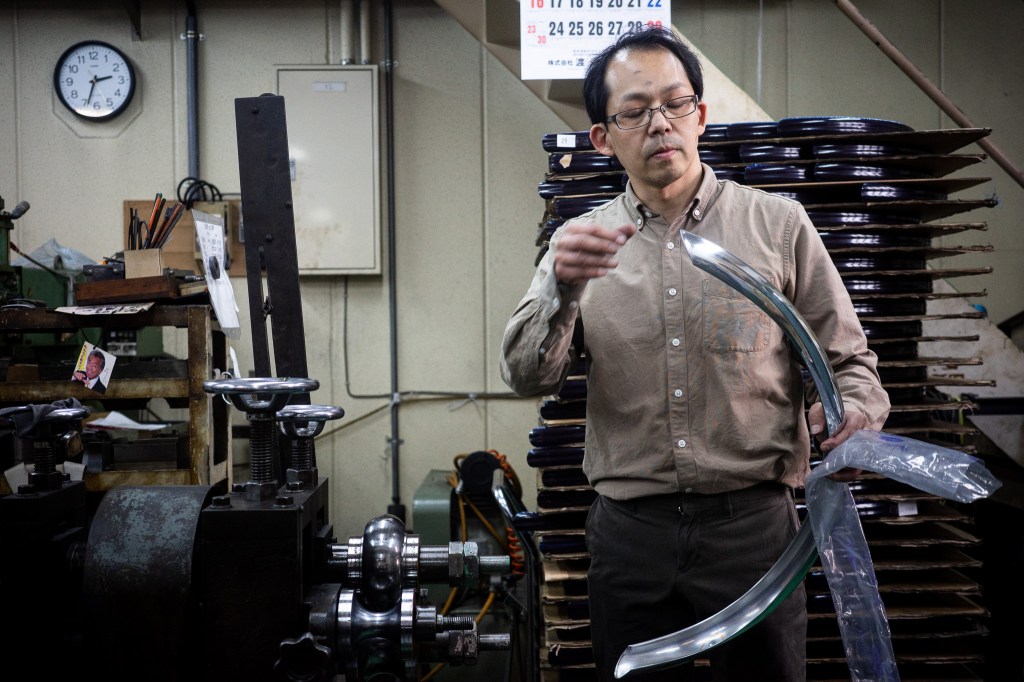

the machinery looked to be mostly if not all original from the late 1940s. on this day, only Tomoyuki and one other employee (pictured above) were bending struts and running these big fascinating machines.

nice machines! this place was full of them. its interesting and heartening to see a generations old family run manufacturing business and living space all under one roof — just don’t get that in the US any more. high end markets for bike stuff can be more expensive, but it allows for this sort of thing to exist long term.

I think this is where Patrick Patz is being shown how the edges fold under. Tomoyuki had been speaking to us through a translator earlier, and now he was feeling confident enough in his English to really get into the details.

above is the extruding machine — anywhere from fenders for road bikes, to these big honkers for motorcycles.

the photo on the right above is the stamping machine for the famous logo.

cute and tidy is the result.

I really want to see the bikes that these fenders will one day end up on after an 8 hour instal. amiright?

the final step is sanding the edge of the edge of the fender. another nice touch that saves the touch, as in your fingers from getting cut on bare metal during your 8 hour instal. its the little things. the details that are just so Japanese.

that is Tomoyuki’s father behind all those bike boxes in the above right photo. wish I’d gotten more photos with him, but right after this photo he welcomed us over and the warmth he spoke to us with had me completely forgetting to take photos.

the hammered fenders are not only unique to look at, but also hide the dents and imperfections one gets from using a smooth fender in the real world. wonder if the dimples make them more aerodynamic? surprised Jan doesn’t try something with that.

and then the tour was over and we bid our farewell to our new friend. but not before his mother came down to bring us some Japanese treats. again, the warmth of this family, and their pride in the product … inspiring. when I dare to put fenders on my bikes from here on out, they will be Hanjos.

hope you enjoyed!

XXRR

Leave a reply to Halldór Örn Gunnarsson Cancel reply