on a rest day from riding, patz and I borrowed a car and took a 3 hr drive to the small factory that make our caps in a rural farm town, 1.5 hrs from Milan. living most of my adult life beneath the stubby shade of one of these things; from this very factory — it felt like a pilgrimage of sorts. through the mountains and onto the autostrada the rolling fields of pasta ingredients gave way to what appeared to be the only business in a small town.

we were greeted by Eleonora, our contact here for the last 5 years. Both Ron’s, and Ultradynamico caps are produced here, as well as all of the Pro Tour teams and many others. it was instantly fantastic to see Eleonora in person — she made us some espresso, and took us upstairs to meet the CEO.

I should note that this is a 3rd generation family company with 40 employees — only 2 of which are men. they are very proud of that, and for good reason. the factory is solar powered, and they re-use all of the water 3 times. I know this can sound green washy, but for some reason, when stated in an Italian accent, it felt fresh.

the sister’s (sorry I can’t remember names) grandfather started the company, and was friends with all the cycling greats — Ernesto Colnago to Eddy Merckx. there was memorabilia to these relationships all over the walls. this place felt holy to a student of cycling.

after a colorful discussion of the products they offer, and what they can do for us moving forward, we were treated to a tour of the inner sanctum of tiny hat production. they allowed me to take a few photos, but for obvious reasons, did not want to give away many secrets to the public and the 30-40 readers of this blog 🙂

much like the old Nutmeg Needleworks, the process begins with a hydraulic press and metal dies that punch out the patterns. above if patz with one of the dies for the cap bodies.

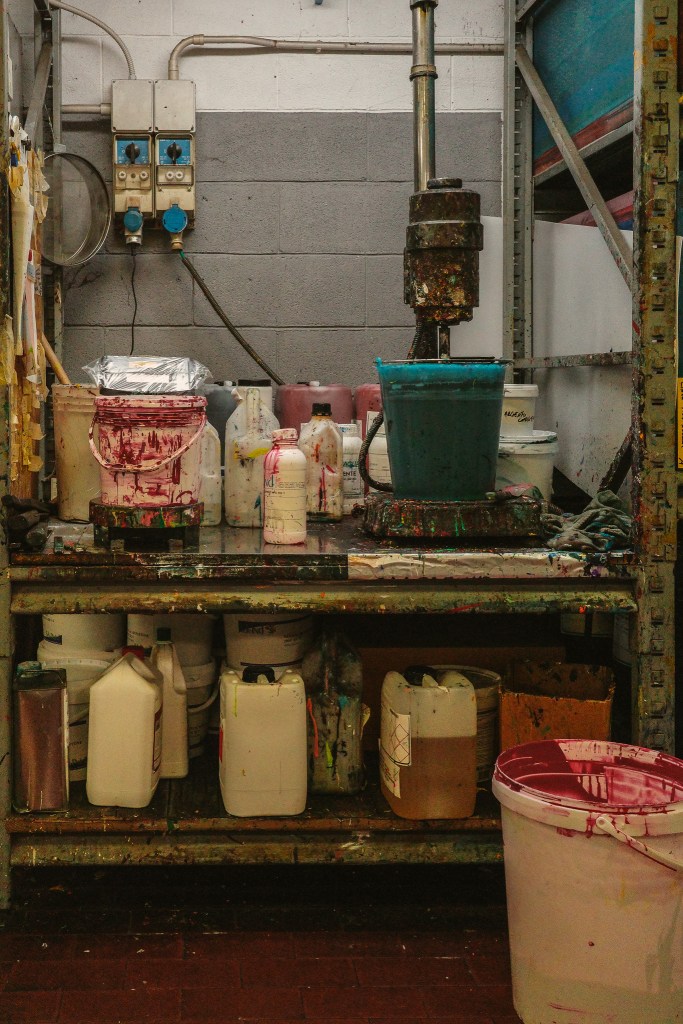

then the cap pieces go to the silk screen room. they color match any Pantone you send them. once a color isn’t used any longer, it gets combined with all the other scrap inks to make black. nothing goes to waste here.

mixing the inks above — I would imagine this would be an important job. you will notice the silk screen frames in the right corner — they are laid out in advance according to the job for the day.

after the pieces are printed, they are put though a giant oven on a conveyor belt for the ink to cure. the sisters reminisced about how when they were kids the cap pieces were hung on a clothes line outside and they just hoped it would not rain.

the caps are then sewn in a sewing room whizzing with 10 sewers and 5 QC inspectors and thread trimmers. this all felt very much like a larger sale version of our old bag factory. pretty cool to see it run so smoothly! they produce 3000 caps a day here. the tape on the left was special ribbon sewn into caps commemorating Francesco Moser’s 1 hr record in 1984.

they also do sublimation of polyester fabrics, but I was not allowed to take photos of that process.

we were then treated to grandpa’s bike collection. here are a few in his size that were traded for caps as I understand. They also told us that Eddy Merckx used to call them personally to place orders. how cool! “ciao”, “yes, this is the Cannibal speaking, can I please order some tiny caps?”

now you know how it’s made. we left feeling very good about it.

XO

Ronaldo

Leave a reply to coolultraromance1598 Cancel reply